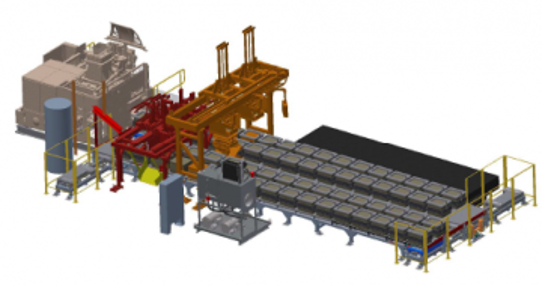

Factory Layout Information

- Area of the plant: 1 Acre

- Total Buildup Area: 42540 Sqft

- Capabilities: Foundry, Metallurgical lab, Core Shop, Fettling & Dispatch Area and Office.

- Key Advantages: Located inside the foundry cluster, Easily accessible from highway.

Material Testing Lab

We have spectrometer with 29 elements in standard calibrations; including N, C, S, P, B etc. All to low levels. Advanced features including auto-identification of grade and matrix, ARQC etc.

Inverted Microscope

We have inverted microscope with image analyzer to check structure of the materials.

Sand Testing Lab

We have testing laboratory with Sand Rammer, Infrared red Moisture Balance, Sieve Shaker, Permeability Tester, and Mould Hardness Tester We also have Brinell Hardness Tester, Universal Testing Machine, Portable Pyrometer.

Core Shooter

- Automatic Core shooter attached with 100 kgs sand mixer

- Capable to produce Cold Box Core, Shell Core & Co2 Core.

- All required cores are being manufactured in-house

- Max. Core weight 10 Kgs

Sand Plant

- Mechanized sand plant with Semi Automatic 300 Kgs sand mixer 2 Nos, 120 T Storage & Polygonal Sieve

- Capable to deliver 24 MT

Melting

- Medium frequency Coreless 500 Kg crucible, Inductotherm Make

- Dedicated 350KVA Power

- One Heat tapped every 1 Hour

Moulding

ARPA 300 2 Machines

- Jolt & Squeeze

- Box Size : 400 x 520 x 100+100

- Weight Range 1 Kgs to 40 Kgs

- Moulds / Hour 50 Moulds

Moulding

ARPA 450 2 Machines

- Jolt & Squeeze

- Box Size : 600 x 700 x 100+100

- Weight Range 40 Kgs to 80 Kgs

- Moulds / Hour 25 Moulds

- Pin Center 800mm

Moulding

Sarvamangala 300

- HPML

- Box Size : 550 x 550 x 150+150

- Weight Range 25 Kgs to 50 Kgs

- Moulds / Hour 40 Moulds